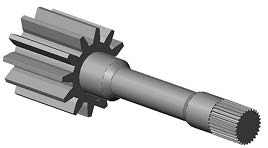

Sprockets

|

|

|

Essential when replacing a turning assembly, DSC is able to offer you an overall solution guaranteeing the longevity of the device. We can offer on stock Caterpillar, Komatsu or Hitachi gear wheels; For all other models, DSC, thanks to a special partnership in custom manufacturing, can provide any model of any brand.

Main technical information of the drive sprocket:

The tooth width of the pinion must always be slightly greater than the toothing of the slewing ring. The difference in width should be about 1 times the module. The recommended gear quality for the sprocket is 8e26, or better quality. In the presence of very high forces on the teeth, we recommend a reduction of the pinion tooth flanks and a curved profile for the teeth of the crown. To allow adjustment of the clearance on tooth flanks, the highest point of the pitch diameter is marked in color. The game on the sides of the teeth must be adjusted here. In the case of applications subject to impact, an appropriate shock factor must be taken into account when determining the maximum drive torque.

Tooth clearance: The tooth clearance is set at the factory at the highest point of the pitch diameter. It depends on the module of the toothing.

Lifespan: The expected life of the toothing depends mainly on the conditions of use. Influential parameters include:

- the training couple

- rotational speed

- the proportion of the service time

- Room temperature

- lubrication, etc.