Definition and technology

Slewing Drives

Definition :

Modular mechanical assembly built on the base of a slewing-ring

Conception :

Slewing drives are compact rotary systems designed to be installed directly on the customer’s applications which give rotational movement to the structure while at the same time are able to withstand high loads and critical environmental conditions due to its enclosed system.

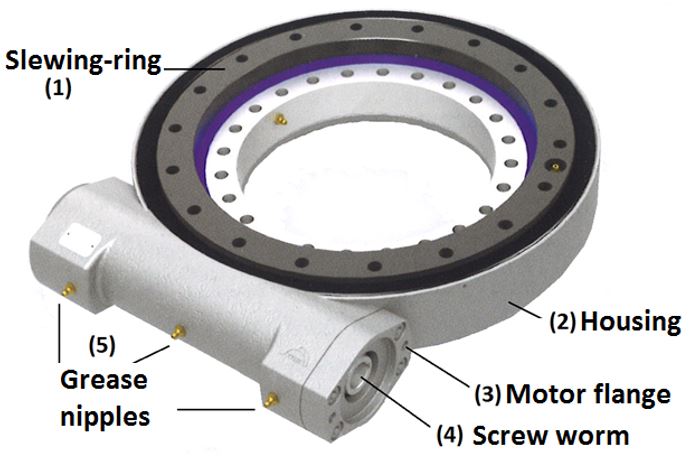

Slew drives are composed by a slewing-ring (1), mounted on or inside a housing (2) wich is where it is also assembled the screw worm (4) which is the part in charge of the transmission of the torque to the slewing-ring. Inside that housing, there are also a couple of berarings wich hold the screw worm together with their corresponding motor cap and encoder cap (3). These caps can be adapted to fit directly a hydraulic motor or a gearbox by means of an adapter flange. The drive has its own grease nipples (5) that allow the re-greasing of the slew drive for maintenance.

Slew drives characteristics:

Slew drives present some characteristics the should be taken into account to choose the proper series for each application. The main points to consider are the ones following:

The maximum output speed must be less than 1rpm.

The standard temperature working range of a slew drive is established between -20 and +70°.

The slew drives can be used both in horizontal and in vertical position. In case installing it in vertical position it is recommended to fix the slew drive with the screw worm on the lower position. For other mounting it’s necessary to consult the technical department.

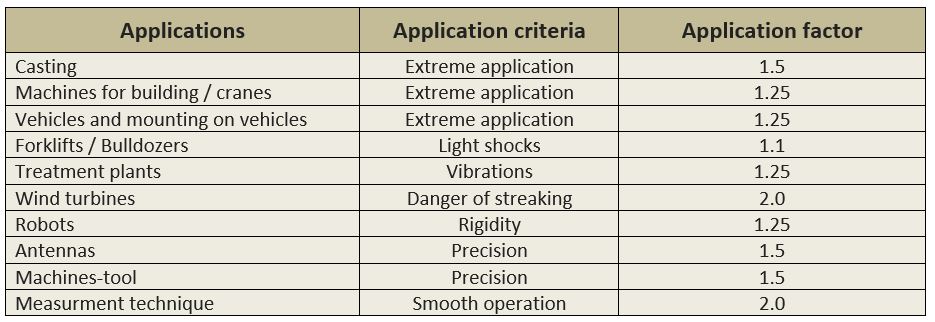

The load diagrams for each drive shows its limit static load with a safety factor of 1. It is recommended adding an application factor to the loads according the following table. To ensure the drive chosen is the right one, the load case of the application must be below the limit curve.

The load diagrams are also limited by the bolts. They are only valid if all the bolts of the slew drive are used to fix it to the structure. The quality of the bolts is considered grade 10.9 the threaded length should be at least 1.5 times the bolt diameter and the recommended flange thickness 2 times the bolt diameter. If the bolt curve does not appear in the chart, this means that this curve is above the slewing-ring chart.

In case you have questions regarding the application for breach of any point of the ones mentioned above or various load cases are applied, it’s recommended to contact technical department. In case the slew drive chosen does not adapt to your application it’s recommended to choose slewing-ring models, as there exist a major variety of products and features.

Differents types: