Definition and technology

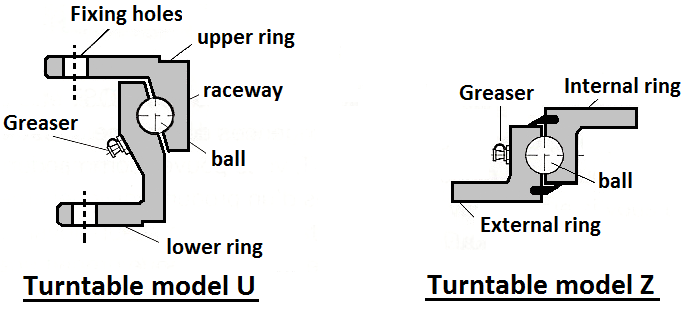

Turntables :

_Page_1_Image_0002.jpg) |

_Page_1_Image_0001.jpg) |

Definition:

Turntables are parts intended for trailers and agricultural vehicles that pivotally connect the sub-frame to the chassis of the trailer.

A turntable consists of two steel flanges, connected by a raceway. A track is machined in each of the two rings so that the transmission of forces via the track is the most favorable. Initial greasing protect the bearing system.

DELIVERY:

The turntables are supplied as standard type being filled with lithium-saponified grease of penetration grade 2 or as a low-maintenance type being filled with Gleitmo 585K.

The turntables are supplied with a surface preservation. This preservation is only temporary protection against corrosion which can be overpainted with any commercial finishing paints and with bituminous paint. ATTENTION: Do not overpaint the seals.

The user should check in each individual case if overpainting is possibly by applyoing a trialcoat and conducting an adherence test. Any coating older than 3 months must be sanded down prior to further surface treatment.

Without adequate surface preparation – sandblasting for example- the applied protective painting does not provide improved protection against corrosion. Storage of the turntable is possible for periods of up to 6 months in roofed storage areas. Storage of up to 12 months is possible, provides that the turntables are kept in a climate controlled environment.

MOUNTING :

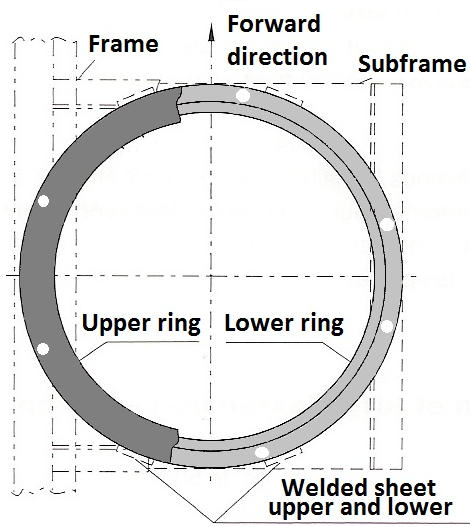

Turntables must be mounted on a flat and torsion-resistant frame structure.

It is the essential that at least 50% of the peripheral surfaces of the flanges are supported load-bearing zones that are roughly equally spaced in the direction of travel and at right angles to this.

The essential factor here is to support the profiled rings of the turntable thus assuring that the forces are directly transmitted into the raceways.

Total out-of-flatness 1.3mm permissible are for example 0.8mm up and 0.5mm down.

Larger out-of-flatnesses have to be compensated by suitable measures (machining of the contact surfaces or use of captive shims in the respective contact area).

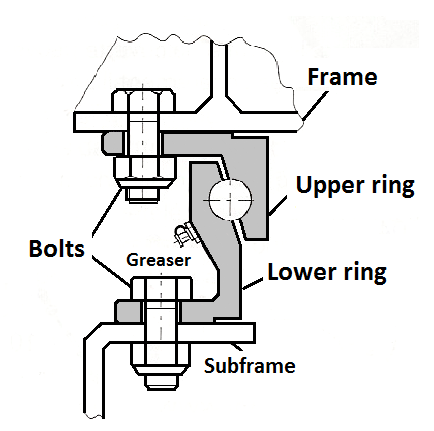

To secure drilling versions of the turntable, high-strength bolts of quality 10.9 as well as high tensile washers must be used in all the mounting holes. On undrilled versions its recommend using at least 8 high-strength bolts of quality grade 10.9 as well as high tensile washers for optimal load transfer. Care should be taken in order to prevent any chips from entering the raceway system and that the turntable, as well as the seals, are not damaged when the drilling mounting holes.

The size and distribution of the bolts must be calculated based on the load.

The turntable must be mounted to the companion structures so that the horizontal forces from acceleration and deceleration are transmitted and the bolts are relieved in radial direction. To prevent distortion from occurring, turntables must never be attached to the companion structure by welding.

The load details and bolt connections are only valid for operation on paved roads and under transport conditions as usual in Western Europe.

Under special operating conditions, example: forestry work, the companion structure has to be protect the turntable in a way than it can-not be damaged by branches or other foreign objects.

The nameplate or filler plug has to be positioned 90 degrees to the direction of travel, i.e. outside the main load-carrying area.

|

|

Lubrication and maintenance:

Standard series:

Prior to installation, the turntable has to be re-greased while turning the upper ring until a collar of grease appears at round the entire circumference of the bearing gaps. A penetration grade 2 lithium-saponified grease should be used for re-greasing. Re-greasing should also be carried out after installation, rotating or slewing the turntable through at least 30° to achieve uniform grease distribution. Re-greasing is required at least once a month. It must be warranted that a sufficient amount of bolt preload is maintained throughout the complete life time of the turntable.

Practical experience has shown that is necessary to re-tighten the bolts with the required tightening torque in order to compensate the settling phenomenon of the bolted connections. The “as-supplied” bearing clearances shown in the bearing tables are permitted to increase through wear by a maximum of 3mm axially and radially. Thereafter, the turntable must be replaced.

Low maintenance design series:

Some turntables models are provided with a long-term lubrication for a low-maintenance period of at least 3 years or a mileage of 300.000kms. The precondition is a protection at the companion structure to prevent water from entering there. Should exceptional environmental conditions prevail or should the turntable be directly cleaned with a high-pressure equipment, it is necessary to re-grease the turntable immediately.

It is recommended that the companion structure protects the turntable in order to prevent any water and dirt from entering the raceway system. This service period can be extended by re-lubrication with Gleitmo 585 K. Re-greasing should be carried out while turning or slewing the turntable through at least +/-30% in order to guarantee a uniform distribution of the grease.

For applications with extreme environmental conditions, specific maintenance instructions have to be established for each individual case. The turntables are equipped with grease fittings. Once the low maintenance operating period has elapsed, it is necessary to re-grease through all grease fittings. Re-greasing should be carried out while turning or slewing the turntable at least +/-30° in order to guarantee a uniform distribution of the grease. It must be warranted that a sufficient amount of bolt preload is maintained throughout the complete life time of the turntable.

Practical experience has shown that is necessary to re-tighten the bolts with the required tightening torque in order to compensate the settling phenomenon of the bolted connections.

It is recommended that axial movement measurements are undertaken in conjunction with acceptance procedures and with technical details provided in accordance with the plan.

If the measurement shows an axial or radial clearance excess of 3mm, the turntable will have to be replaced.

Description of how to measure the axial movement measurement:

- Check the bolt connections.

- Position the dial gauge with integrated magnets between the superstructure and the undercarriage in axial direction close to the raceway and o bolted area.

- Set the dial gauge to zero.

- Lift the superstructure by a forklift or lifting tackle until the undercarriage is freely suspended.

- Read the dial gauge to observe the axial movement.

- Position the dial gauge on the other side and repeat the above sequence of steps

Other conditions of use:

- Should turntables be applied in vehicles with less accelerations or decelerations than indicated, the permissible axial load can be increased.

- Generally turntables are suitable only for turning movements of +/-180°.