Nuts and bolts

Definition

The bolt is an assembly consisting of a screw head (default precision: hexagonal) and a nut that fits, and intended to ensure a clamping between the bearing face of the head of the screw and one of the faces of the nut. Unless otherwise specified, the bolt does not normally include a washer.

Description

In bolts, the term screw corresponds to a complete thread while the correct term is bolt body when the threaded part is partial. For example, a hexagonal head bolt corresponds to ISO 4014 if the thread is partial and to 4017 if the thread is complete (under head).

A bolt creates a complete connection, rigid and removable, between the pieces it passes through and presses against each other. In fact, the bolts (and the machine screws) act like very stiff springs whose elasticity makes it possible to maintain the tightening of the parts in spite of the influence of external factors such as mechanical actions, vibrations or temperature rises. . One or more washers placed on either side of the parts make it possible to better distribute the compressive force, to resume the eventual matting of the surfaces and / or to protect the substrate from unwanted deformations. An additional nut (locknut) can slow down the assembly and prevent it from loosening. The name bolt integrates, by extension, these complementary equipments. The bolt is a prestressed assembly device.

Indeed, the mechanical traction held in the rod causes a friction which prevents the rotation of the head of the screw and that of the nut relative to the fixed part. As soon as this traction disappears (flattening of the contact surface in +/- 15 min, creep in +/- 10 years), the assembly perishes.

Various devices make it possible to prevent loosening of the nut, by mechanical stop (washers to be folded down, drilling and passage of 'wire to brake' in aviation and motorcycle racing, pinning, castle nuts), or by the effect of tightening in particular split and elastic ("Grower" or "W") brake washers, corrugated, serrated ("fan" or "AZ"), by braking the nut itself (Nylstop nuts, flanged); the modern trend is to stick with anaerobic adhesives, removable by heating or brute force.

Definition features of a bolt

About stems:

- head shape: hexagonal, square, cylindrical, countersunk, hexagon socket, Torx, XZN, diamand, halfen ...

- arrangement of the head, linked to the maneuvering system: slot, impression, etc. (for flat or Phillips screwdrivers, Allen key, Torx, ...)

- rod length and thread length (defined by standards),

About nuts:

- shape (hexagonal by default),

- height.

Those common to both:

- nominal diameter of the thread,

- thread profile and thread,

- material (steel E36, E24, 35CD4 ... Stainless steel, aluminum, platinum ...)

- class of materials (strength criteria: class 4.6, 5.8, 6.8, 8.8, 10.9, 12.9, A70 ...).

The first digit corresponds to one-tenth of the value of the tensile strength limit, expressed in daN / mm². The product of the 1st by the 2nd digit of the class gives approximately the elastic limit in daN / mm².

- coating - only for steel bolts - (hot dipped galvanized, electrogalvanized, bichromated, raw ...)

Example designation: CHc bolt M8x1-50, 8.8 Zn

The coating and the material of the bolt are very important because of the electrochemical couples involved.

Objectives screws connections:

- Ensure a permanent connection between the parts to be assembled, taking into account a cost and an economic life.

- Allow these same parts to support and transmit normal and planned efforts from the design of the structure.

- Reduce the risk of destruction of these parts, even during slightly higher efforts (integration of safety factors).

- Reduce the oscillations at risk (shear, bending, torsion) on fastening parts and give priority to tensile or compressive stresses.

- Minimize the impact of external dynamic loads, for which mechanical resistance is very low.

- Take into account the external constraints related to the surrounding environment (forces, vibrations, shocks, temperature, humidity, pollution, corrosion)

- Correspond to the professional uses, standards and rules of design safety (sizing, class), assembly (tooling, procedure, control)

Fixing function on the slewing ring :

In order to be able to transmit the defined forces, it is necessary to make a suitable mechanical fastening of the slewing-ring on the associated frames thus making it possible to fully secure the crown and its supports.

Several modes of attachment are feasible, the most effective method is the connection screw / nut. Welding operations are totally out of the question.

The correct definition of the fixing bolts and its implementation in accordance with the rules of art, condition the proper operation of the slewing-ring and the safety of the application.

The quality of the bolts:

The ISO 898-1 standards define the quality classes of bolts adapted to structural assemblies such as slewing rings. It is highly recommended the use of HIGH RESISTANCE CLASS 10.9, and exceptionally classes 8.8 or 12.9.

The nuts must be of a class equal to or greater than that of the associated screw. For a d-type screw, a nut height is recommended. The use of treated flat washers is necessary.

Hexagonal head screws are preferred over cylindrical head screws whenever possible.

In all cases it is recommended to supply bolts (screws + nuts) with guaranteed mechanical characteristics, matched and pre-lubricated to obtain a constant and known value of friction coefficient screw / nut. Surface treatments carried out on the bolting must not cause any weakening effect.

|

Regarding the procedure for mounting and tightening the bolts on the slewing-ring refer to the manual of mountingand maintenance of slewing rings. |

Bolts generally used for mounting slewing-ring :

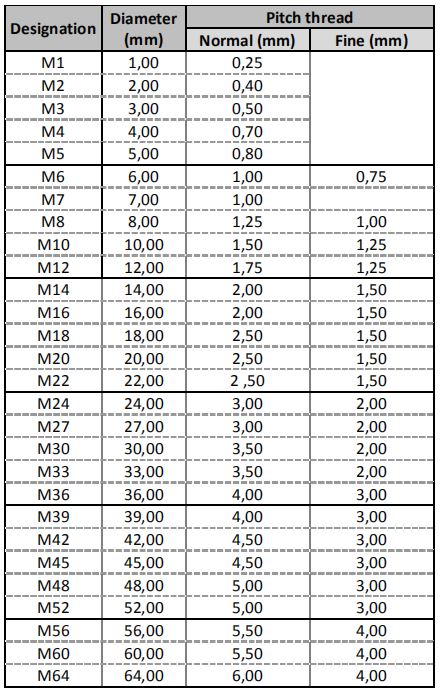

Definition of pitch thread